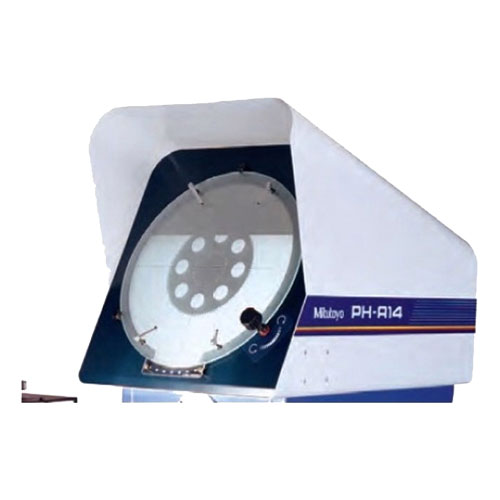

Quality

We expect the same in our measuring tools. That is why we use the best tools and the newest technology available in the industry and keep a rigorous annual professional calibration system.

Our QC department is certified in interpreting drawings per ASME Y14.5M-1994 and also has the capability to inspect parts in their native CAD formats to eliminate the detrimental effects of file conversion. As we strive for continuous improvement and efficiency we are able to eliminate waste and pass on saving to customers. We have implemented the use of electronic height gages on the shop floor to facilitate, increase accuracy and precision, and reduce in-process inspection time.